The Ultimate Guide: Creating Robust Backup Plans for Equipment Failures

What would you do if the sound system failed in the middle of your event? Panic sets in.

How do you avoid such crises?

As a life coach, I’ve helped many professionals navigate these challenges. In my experience, I often encounter event planners struggling with equipment failures, highlighting the need for robust event equipment backup strategies.

In this article, we’ll explore specific strategies for creating backup plans. You’ll learn how to conduct risk assessments for equipment malfunction, develop redundancy plans, and implement preventive maintenance scheduling techniques.

Let’s dive into event equipment backup strategies.

Understanding Equipment Failures and Their Impact

Let’s talk about the common issues that can derail an event. Equipment malfunctions, such as sound systems failing, projectors not working, or lighting issues, are frequent culprits. Implementing event equipment backup strategies is crucial to mitigate these risks.

These malfunctions can turn a perfectly planned event into a chaotic scene. In my experience, clients often face significant disruptions and financial losses because of such unexpected failures. Proper risk assessment for equipment malfunction can help prevent these scenarios.

Believe me, the costs can add up quickly. You might have to refund tickets, lose valuable time, or damage your reputation. Minimizing production losses during equipment failures is essential for event success.

Many event planners initially struggle with these challenges. They often don’t realize the importance of being proactive until it’s too late. Developing emergency response protocols for machinery breakdown is a key aspect of event equipment backup strategies.

You don’t want to be in that position.

Roadmap to Create Effective Backup Plans for Event Equipment Failures

Overcoming this challenge requires a few key steps. Here are the main areas to focus on to make progress with event equipment backup strategies:

- Conduct risk assessments for critical equipment: Identify crucial equipment and analyze historical data to predict issues, implementing risk assessment for equipment malfunction.

- Develop redundancy plans for key systems: Establish backup equipment and create detailed contingency procedures for manufacturing downtime, including emergency response protocols for machinery breakdown.

- Implement regular equipment maintenance schedules: Schedule preventive maintenance and use data-driven predictive maintenance strategies to anticipate failures, minimizing production losses during equipment failures.

Let’s dive into these event equipment backup strategies!

1: Conduct risk assessments for critical equipment

Ensuring the reliability of your equipment begins with thorough risk assessments, a crucial step in developing event equipment backup strategies.

Actionable Steps:

- Identify critical equipment: Compile a list of all essential tools used during events. Prioritize them based on their importance to event success and consider risk assessment for equipment malfunction.

- Review historical data: Analyze past events to pinpoint common equipment failures. Utilize this data to predict potential issues in future events and develop data-driven predictive maintenance strategies.

- Engage stakeholders: Involve staff, technicians, and vendors in discussions. Collect their insights on vulnerabilities and possible solutions, including contingency planning for manufacturing downtime.

Key benefits of conducting risk assessments:

- Proactive problem identification

- Improved event planning

- Enhanced equipment reliability

Explanation: Conducting risk assessments helps you anticipate and mitigate equipment failures. By engaging stakeholders and using historical data, you can develop a proactive approach to event equipment backup strategies.

This aligns with the industry trend of using comprehensive risk assessments to enhance reliability and resilience.

Starting with these steps ensures you’re prepared to handle any equipment issues that may arise, minimizing production losses during equipment failures.

2: Develop redundancy plans for key systems

Creating redundancy plans for key systems is crucial to ensure your event runs smoothly despite equipment failures. Implementing effective event equipment backup strategies is essential for success.

Actionable Steps:

- Establish backup equipment: Maintain spare equipment for critical systems, such as backup microphones and projectors. Store these backups in accessible locations, similar to inventory management for critical spare parts.

- Create detailed contingency plans: Develop step-by-step procedures for switching to backup equipment. Assign roles and responsibilities for executing these plans seamlessly, akin to emergency response protocols for machinery breakdown.

- Conduct regular drills: Schedule routine emergency drills to test your contingency plans. Use these drills to identify and address any weaknesses in your procedures, similar to risk assessment for equipment malfunction.

Explanation: Implementing redundancy plans helps mitigate the impact of unexpected equipment failures. By having backup equipment and detailed plans, you can quickly address issues and keep your event on track, minimizing production losses during equipment failures.

This aligns with the trend of using backup plans in various industries to enhance reliability and preparedness.

Essential components of effective redundancy plans:

- Clearly defined roles and responsibilities

- Regularly updated equipment inventory

- Frequent testing and refinement

These steps will ensure you are prepared to handle any equipment issues that may arise, incorporating event equipment backup strategies throughout your planning process.

3: Implement regular equipment maintenance schedules

Implementing regular equipment maintenance schedules is crucial to prevent unexpected failures during your events and is a key component of event equipment backup strategies.

Actionable Steps:

- Schedule preventive maintenance: Create a calendar for regular inspections and servicing of all critical equipment. Ensure these tasks are performed consistently, utilizing preventive maintenance scheduling techniques.

- Use predictive analytics: Deploy tools that analyze data to forecast potential equipment failures. Schedule proactive repairs based on these insights, employing data-driven predictive maintenance strategies.

- Train staff: Educate your team on basic troubleshooting and maintenance tasks. Encourage a proactive approach to equipment care and reporting, including cross-training employees for equipment troubleshooting.

Explanation: Regular maintenance schedules help you stay ahead of potential issues, ensuring smooth event operations and minimizing production losses during equipment failures.

By using predictive analytics and training staff, you can minimize disruptions and extend the life of your equipment. This aligns with the industry trend of using predictive maintenance tools to enhance reliability and efficiency, which is essential for contingency planning for manufacturing downtime.

Key advantages of regular maintenance:

- Reduced downtime during events

- Extended equipment lifespan

- Cost savings on repairs and replacements

Consistent maintenance ensures that your equipment remains in top condition, reducing the risk of unexpected failures and supporting effective event equipment backup strategies.

Partner with Alleo for Event Success

We’ve explored event equipment backup strategies for managing equipment failures and minimizing disruptions. But did you know you can work directly with Alleo to make this process easier and faster?

Using Alleo, you can set specific goals for risk assessments, redundancy plans, and preventive maintenance scheduling techniques. It helps you prioritize and allocate time for these tasks, including contingency planning for manufacturing downtime.

Alleo provides data-driven insights to identify critical equipment and potential risks. You get personalized advice on developing effective contingency plans and emergency response protocols for machinery breakdown.

Alleo assists in building habits for regular maintenance and emergency drills. It offers reminders and progress tracking to keep you on top of your preparedness activities, including cross-training employees for equipment troubleshooting.

Ready to get started for free? Let me show you how to implement cost-effective backup equipment solutions!

Step 1: Log In or Create Your Alleo Account

To start planning your event backup strategies, log in to your Alleo account or create a new one if you’re a first-time user.

Step 2: Choose “Building better habits and routines”

Click on “Building better habits and routines” to develop consistent practices for equipment maintenance, risk assessments, and emergency drills, ensuring your events run smoothly without unexpected failures.

Step 3: Select “Career” as Your Focus Area

Choose “Career” as your focus area to address event planning challenges and equipment failures, enabling you to develop professional skills in risk assessment, contingency planning, and equipment maintenance that are crucial for success in the events industry.

Step 4: Starting a coaching session

Begin your journey with Alleo by scheduling an initial intake session to assess your event planning needs and create a tailored strategy for implementing backup plans and equipment maintenance schedules.

Step 5: Viewing and managing goals after the session

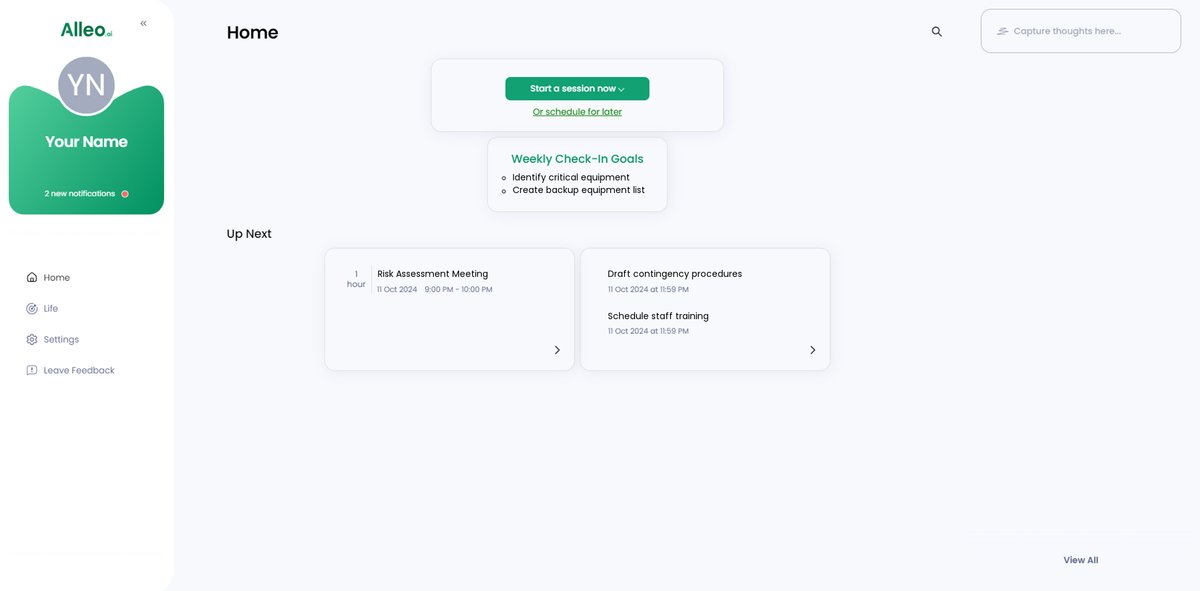

After your coaching session, check the Alleo app’s home page to review and manage the event backup plan goals you discussed, ensuring you stay on track with your risk assessments, redundancy plans, and maintenance schedules.

Step 6: Adding Events to Your Calendar or App

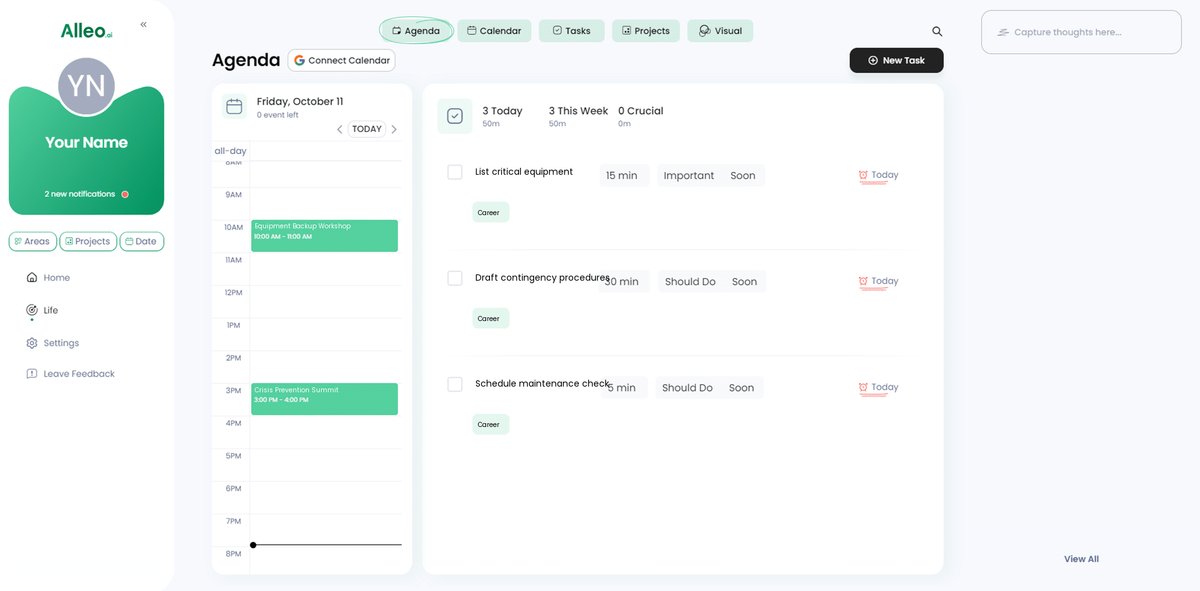

Use Alleo’s calendar and task features to add and track your equipment maintenance schedules, risk assessment meetings, and emergency drills, ensuring you stay on top of your event preparedness activities and can easily monitor your progress in solving equipment failure challenges.

Final Thoughts: Ensuring Event Success with Backup Plans

We’ve covered a lot today, from identifying risks to creating redundancy plans and maintaining equipment. These steps are crucial to avoid the chaos of an unexpected failure and are essential event equipment backup strategies.

Remember, equipment malfunctions can turn a great event into a disaster. But you have the tools to prevent that through effective risk assessment for equipment malfunction.

By conducting risk assessments, you can anticipate and address potential issues. Developing redundancy plans ensures you’re always prepared, much like contingency planning for manufacturing downtime.

And regular maintenance keeps everything running smoothly, akin to preventive maintenance scheduling techniques.

I know it can seem overwhelming, but you’re not alone. Alleo is here to support you every step of the way, helping you implement event equipment backup strategies.

Imagine the peace of mind knowing every detail is covered. Take action now to ensure your events are always a success, minimizing production losses during equipment failures.

Ready to simplify your crisis management? Try Alleo for free today and start planning with confidence, incorporating robust event equipment backup strategies.